Lubretec Wire Rope Lubricator, Complete Grease Unit for 24mm wire - IZ-WRLD01A024

€ 1,113.00 Excl. VAT

Lubretec Wire Rope Lubricator, Complete Grease Unit for 24mm wire

The Wire Rope Grease Applicator Unit is a comprehensive solution designed to streamline and enhance the lubrication of wire ropes in demanding industrial environments. It is especially valuable in industries like construction, mining, marine, and offshore drilling, where wire ropes are constantly exposed to wear and tear. Proper lubrication is key to extending the lifespan of these ropes and ensuring their optimal performance.

Wire Rope Grease applicator unit contains :

• 2 applicator shells

• Full set of seals for specific wire diameter

• ¼ “ connector for grease hose

Key Components of the Unit:

1. 2 Applicator Shells:

• These shells enclose the wire rope during lubrication, ensuring even and efficient grease application along the rope's surface.

• Built for durability, they can withstand tough industrial conditions and are designed to fit various wire rope sizes for a versatile application.

2. Full Set of Seals for Specific Wire Diameters:

• The kit includes seals tailored to specific wire diameters, ensuring a tight fit and preventing grease from leaking during application.

• These seals help to contain the grease within the applicator shells, maximizing efficiency and reducing waste.

3. ¼” Connector for Grease Hose:

o A standard ¼” connector for the grease hose ensures a secure and leak-proof connection to the applicator unit, allowing for consistent pressure and smooth grease flow throughout the lubrication process.

Now Available:

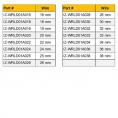

Wire Rope Lubricator – Complete Grease Unit for the following wire diameters:

• 16mm, 18mm, 19mm, 20mm, 22mm, 24mm, 25mm, 26mm, 28mm, 30mm, 32mm, 33mm, 34mm, 36mm, and 38mm wire

Benefits of Using the Wire Rope Grease Applicator Unit:

• Increased Efficiency: This complete grease unit ensures thorough lubrication in a single pass, saving time and reducing manual effort.

• Prolonged Equipment Life: Regular lubrication protects wire ropes from corrosion, wear, and friction, extending their lifespan and reducing the need for frequent replacements.

• Reduced Maintenance Costs: Properly lubricated wire ropes require less frequent maintenance, resulting in long-term cost savings.

• Environmentally Friendly: Precise grease application minimizes waste and reduces the risk of environmental contamination.

• Versatility: With compatibility across a wide range of wire diameters, this unit is ideal for various industrial applications, ensuring you have the right solution for all your wire rope lubrication needs.

This complete grease unit is an essential tool for ensuring the longevity and performance of your wire ropes, offering a reliable, efficient, and versatile lubrication solution across different wire sizes.